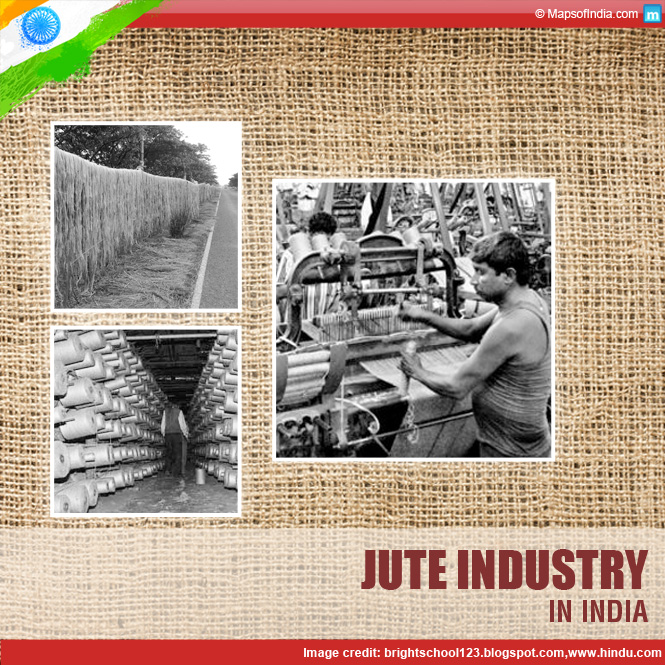

After agriculture; textile and garment sector is the second major job provider in India and has the ability to drive economy. But for that, India needs to explore it further to present something different to the world. Jute industry, a part of textile and garment sector has vast hidden abilities in this regard.

Facts about Jute Industry in India

Presently there are 78 jute mills in India and out of total, 61 are located in West Bengal, 3 each in UP and Bihar, 7 in Andhra Pradesh and one each in Assam Orissa, Chhattisgarh, & Tripura.

As on April 1, 2014, the Jute industry provides direct employment to 215,000 workers in organized mills and indirect employment to 150,000 workers. It provides livelihood to near about four million farm families who are engaged in the cultivation of jute.

Total production of raw jute in 2013-14 was 11,416.4 thousand bales (1 bale 180 kg) or 2.05 MT whereas production of jute goods was 15.3 lakh MT. For the past three years there is no major change in the production of raw material and goods.

India exported about 1.3 lakh MT worth Rs 1,593.6 crore jute and jute products during April-December 2013. The US, the UK, Saudi Arabia, Germany, Egypt and Turkey are the major importing countries.

A brief history

The first attempt to spin jute was made by a spinner in Dundee, UK in 1832-33. With the help of machines he spun jute by blending it with other fibres. Two years later procedure to spun 100% jute yarn by applying whale oil and water was found out.

In India the first Jute mill was set up in 1855 near the present Hasting Jute Mill. Within ten years the quality of jute produced in India crossed the one produced in Dundee.

Till 1947 70% of the jute products manufactured in Indian jute mills were finding their place in the global market. But partition of India was the major set back to this industry because most of the Jute mills came under East Pakistan (now Bangladesh). India became dependent on Pakistan for her raw material needs.

Above that discovery of synthetic packing material, an alternative to jute had jolted the jute industry in India further. This led to a rapid decline in the export of jute and jute products. From 70% the export of goods declined to 30%. The jute industry started to shrink.

Seeing this, the government of India in 1987 declared the Mandatory Jute Packaging Act (PJMA) 1987. Government imposed the use of jute for packing traditional material like food grains and sugar. Currently the share of jute goods export is close to 12% against the total production.

It is one of the major industries in eastern regions of India. If planned well it can generate new employment opportunities.

Jute packing is 100% safe for being natural, biodegradable, renewable and eco-friendly.

Domestic market of jute products is enormous. 90% of the total produce is consumed in India only.

Weakness

Lack of Research and Development (R&D) initiatives is a major weakness of this industry. Moreover PJMA guidelines are changed very frequently which leads to lots of confusion. Investors are generally in dilemma whether to invest in jute industry or not.

Machines used in jute industry are quite old and obsolete. These cannot produce the required quantity and quality of jute. It has been found out that the 150 years old industry runs on obsolete machinery.

National Jute Policy, 2005 put efforts to revamp the domestic jute industry. It started modernizing the industry through technology but only few mills were able to utilize the funds. Jute Manufacturers and Development Council (JMDC) returned the huge portion of fund i.e. Rs 80 crores after utilizing Rs 10 crores.

Jute industry is still following the traditional way of marketing. To grow it must use the modern ways of promoting its products.

Wages given to jute worker is also very less as compared to other sector. It is approximately Rs 50-250 per manday. Government must take immediate steps to make amendments in wage structure. India must work hard to make its jute products a brand across globe.

What can be done?

Application of jute area must be increased. India needs to work on quality by adopting new technologies. Jute Research Association such as JTRL, IJIRA, Institute of Jute Technology must work to utilize resources for the betterment of the industry. Government must make efforts in R&D to strengthen the crisis-stricken but one of the oldest industries in India that is the Jute Industry.