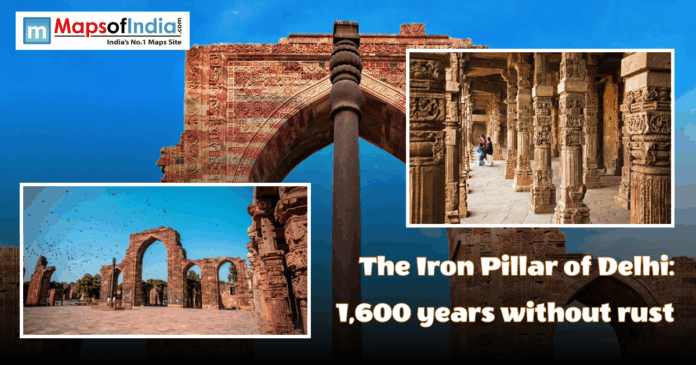

Quietly rising in Delhi’s Qutub complex sits the Iron Pillar. Over 1,600 years have passed, yet it shows no sign of rust. Dating back to the 4th century CE, the pillar reaches seven meters high. More than six tonnes is what it weighs. Its surface carries nothing, no coating, just iron. Still, the pillar shows hardly any rust despite having no modern coating. Even after years under open air, it appears nearly new. People reach out and run their hands along its surface every single day. Backs pressed against it, they walk around slowly, believing something might change. Research never stops, experts keep testing what it’s really made of. Something strange lives in how it just won’t rust. Not like time touches everything else.

Forged During the Gupta Golden Age

Sometime near the year 400, workers poured metal for the column under the Gupta rule. Some experts say Chandragupta II, also known as Vikramaditya, ordered it built. Praise for dedication to Vishnu appears carved in Sanskrit letters. Victories against foes show up in the words chiselled there. At first, this structure did not stand where we see it today. From the Gupta era came skilled metal work. High heat melted iron into form. Sections were joined through careful hammering. This happened when Qutubuddin Aibak brought it to Delhi centuries ago. Much like a structure rising in science’s brightest time in India.

Physical Size and Build

From the earth it climbs seven twenty-one meters high. Below, one fifty stays hidden underground. Forty-eight centimetres wide at its foot. As it moves upward, the width slowly shrinks. The top takes the form of a flared bell. At the peak sits a lotus pattern, softly finished. It weighs over six tons. Purity of iron holds strong through time. Almost no carbon was found inside. Not a trace of slag caught within. Marks left by hammers suggest old methods used long ago. One huge shape shaped by hands that knew their craft.

The Rust-Resistant Composition

Weeks pass, then regular iron begins to corrode under Delhi’s damp air. Almost no rust appears on the ancient pillar, though. Careful study followed when researchers took pieces for testing. Uncommon levels of phosphorus show up about 1.0 to 1.2 per cent. That amount helps build a shield against decay. A mix of iron phosphate and iron hydrogen phosphate slowly grows instead. A film stays light but tough. Because it blocks air and dampness from getting to the surface. Tiny bits of manganese together with silicon show up. Chromium is missing. Nickel does not appear either. Much like a blend formed by chance long ago.

The Protective Passive Layer

A thin skin builds up, just half to one-tenth of a millimetre deep. Though it looks dull, light still slips through. Tiny cuts fix themselves without help. When storms pass, water drags off what’s floating free. Water vanishes fast when the air is parched. Over hundreds of years, the coating inches forward. Today’s steel mixes in chromium to resist rust. Long ago, metal workers found a way without it. A hidden layer builds, tougher as days pass.

Forging and Heat Treatment Insights

Heat changed raw iron lumps again and again under old-world hammers. Impurities vanished slowly through steady pounding. What stayed behind was soft, low-carbon metal. Even spread of phosphorus marked its makeup. Cooling happened slowly on purpose to avoid cracks inside. Finishing touches may have come while shaping the hot piece. A single spot endured blow after blow, slowly hardening under pressure. Not unlike steady hands shaping something close to pure iron through patience alone.

Comparing Old and New Stainless Steel

A thin shield of chromium oxide keeps stainless steel from rusting. When at least 10.5 per cent chromium is present, that protection forms. With nickel mixed in, the material holds up better under stress. Because of these elements, it costs more compared to regular iron. Protection like Pillar’s doesn’t need costly metals. Instead, phosphorus steps in to help. An old technique shows it lasts and works well. Just like what nature built long before modern labs: a natural kind of stainless steel from sixteen centuries past.

Modern Scientific Studies

From IIT Kanpur came a deep look at sample structures. What sat on the surface was checked using X-rays. Light scattering patterns gave away iron phosphate signals. Tests tied to electric behaviour tracked how fast rust formed. Almost no breakdown appeared when the results were reviewed. A harsh test under fake sun showed it barely wears down. Much like science backing up what you can plainly see.

Metalwork Mastery in Ancient India

Out of nowhere, the Gupta era forged iron so fine it still turns heads today. Standing tall in Delhi, an iron pillar shows barely a mark after all these centuries. Other old places have metal columns too, yet none shrug off rust quite like this one. Knowledge flowed quietly from elder to apprentice, hand to hand. Time wore many things thin – this craft stayed strong. Maybe knowledge vanished when the Gupta era ended. Think of it like how we no longer understand old Indian metal techniques.

Tourism and Culture Importance

Outside the tall tower, crowds arrive every year without fail. Close by its foot sits a metal column untouched by time. The smooth finish surprises most who see it up close. Some reach out to brush it, hoping fortune follows. Snapshots happen here more than anywhere else nearby. Signs with short notes break down how it resists decay. Every so often, school outings lead kids to places that feel precious. These visits spark awe while building a quiet sense of belonging.

Preservation Challenges Today

Slowly, air pollution eats at the quiet outer shell. Over time, acid rain wears down the face of it piece by piece. With every visitor’s hand, small marks build up bit by bit. Because of this, ASI limits who can come near, step by cautious step. Checks happen often, without pause. Yet what shields it stays thin, almost too little. Much like an old thing from long ago, always asking for soft hands and steady eyes.

Why It Continues to Influence Researchers

What makes ancient metalwork puzzle today’s experts? Old-time blacksmiths reached amazing cleanliness. Yet why does phosphorus spread evenly through it? The way a quiet coating developed still stumps researchers. Searching continues for clear results. In labs, copies get examined closely. Old methods are explored in detail. A link forms – connecting forgotten skills with what might come next.